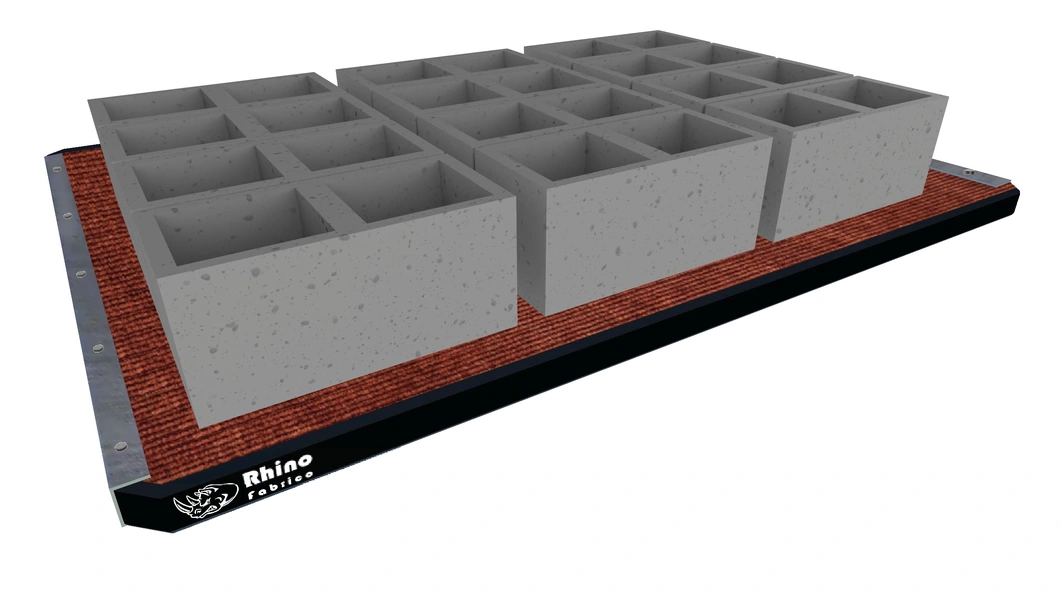

Concrete Block Machine Pallets

RHINO Hardwood Composite

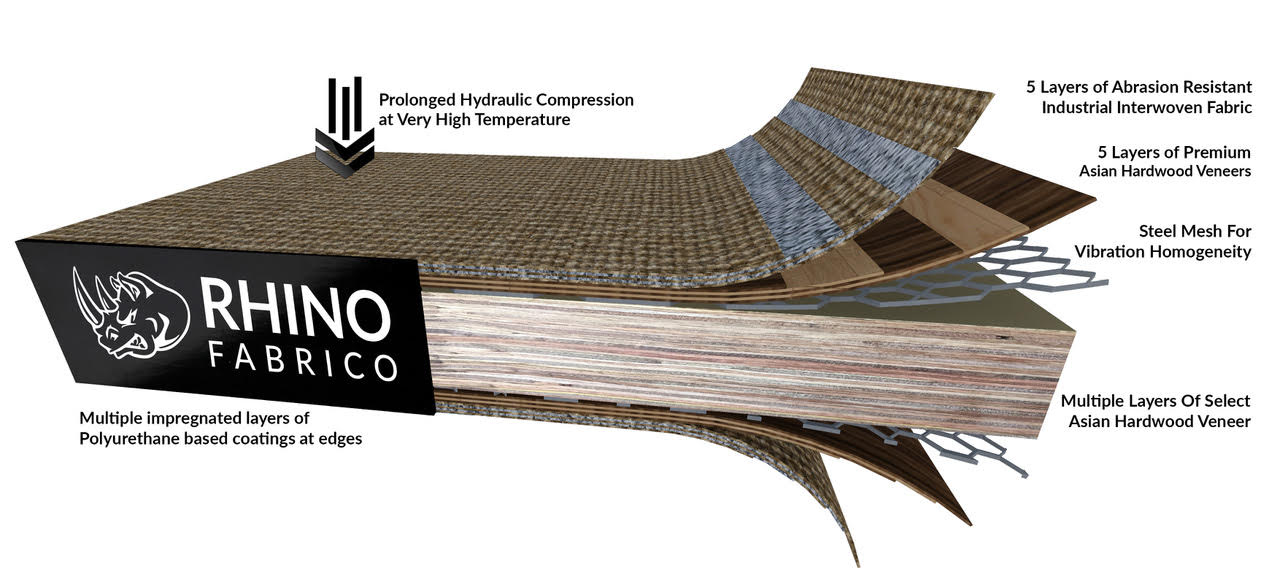

Rhino Fabrico

Premium concrete block machine pallets. Multi layered abrasion resistant surface protection on densified hardwood fibres. Made with waterproof resin.

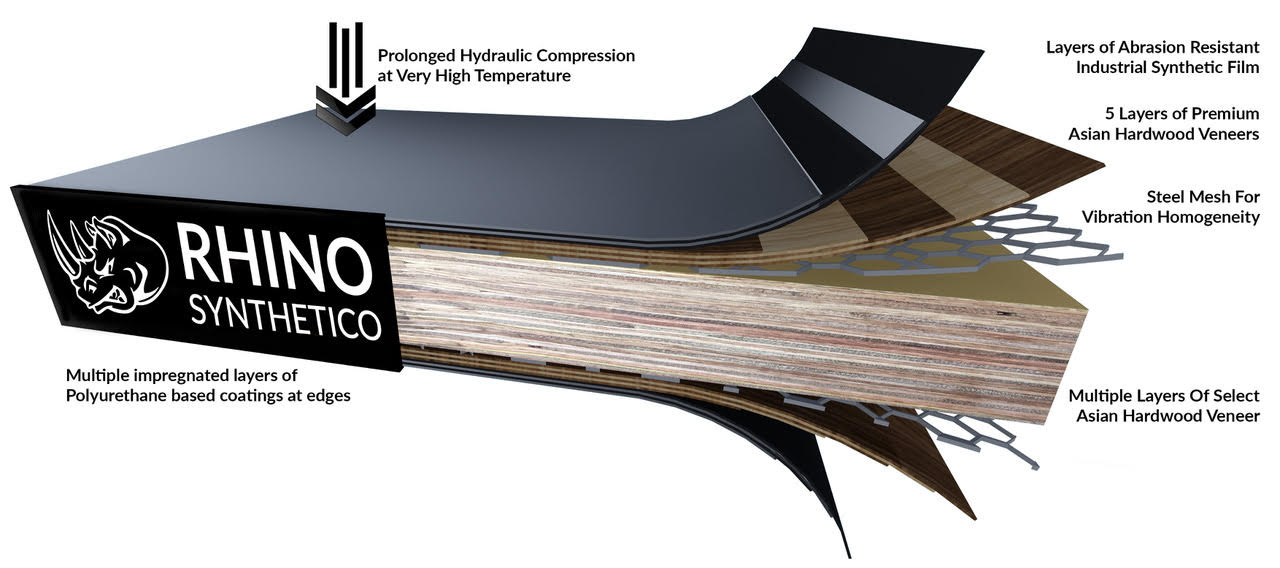

Rhino Synthetico

Concrete block machine pallets with multi layered synthetic film protection surfaces. Densified hardwood for long life. Made with waterproof resin.

Rhino Hardwood Composite Pallets for Concrete Block Machine

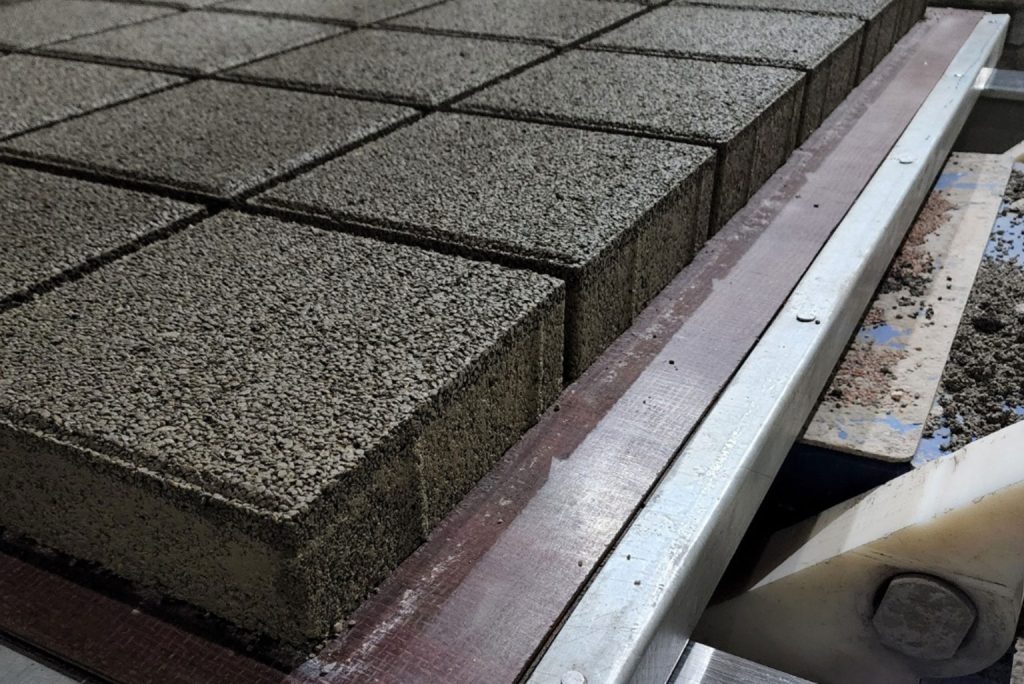

RHINO Hardwood Composite pallets are manufactured from high-grade densified engineered hardwood to give it superior strength and durability. Hard-wearing lamination on top and bottom surfaces ensures excellent resistance to abrasion by pallets during concrete block production. The concrete block and paver manufacturing pallets, or production pallets, are single solid boards with no joints or gaps. Treated individually with industrial-strength waterproof resin, hardwood fibres are pressed under very high pressure and temperature. This creates exceedingly strong pallets for concrete blocks and pavers.

RHINO Hardwood Composite CONCRETE BLOCK MACHINES PALLETS

RHINO hardwood concrete block machine pallets are designed and manufactured to last longer in an abrasive environment. They are created in a distinctive way ensuring that hardwood fibres are arranged as reinforcing elements thereby giving great strength and durability. Use of waterproof resin during manufacturing ensures that our pallets stay resistant to moisture absorption. Steel mesh reinforcement on both sides of the pallet gives additional reinforcement to the pallet. It also ensures homogeneous distribution of vibration across the whole pallet surface.

Such a modern manufacturing process ensures that RHINO pallets outlast many other kinds of materials. They are designed with high level of engineering to eradicate problems associated with pallets made from other materials, like plastic, softwood and steel.

Our inhouse Research & Development has repeatedly confirmed superiority of scientific manufacturing processes in the creation of RHINO concrete block machine pallets. The sturdy hardwood used for manufacturing RHINO hardwood pallets has overcome quality issues arising from rusting, heavyweight and unevenness of steel surfaces. With a highly densified structure, vibration transmission to the green concrete is maximised resulting in higher production and reduced cycle time to our clients.

FSC Certified

All the hardwood used in our boards is always FSC certified. Minimises the impact on our jungles.

VIBRATION TRANSFER

Steel mesh & high density ensures efficient and uniform transmission of vibrations to concrete.

ABRASION RESISTANT

Pallet surfaces are protected with multiple types of abrasion resistant films for long life span.

ABRASION RESISTANT

Pallet surfaces are protected with multiple types of abrasion resistant films for long life span.

RHINO Fabrico

Long lasting premium pallets

RHINO Synthetico

Hardwood with waterproof resin

Advantages of RHINO

Hardwood Composite Pallets for Concrete Block Machine

PLANTATION HARDWOOD

Environment Friendly as only selected plantation hardwood is used.

STEEL C PROFILES

Secure the edges with Galvanised Steel C Profiles for longer life.

LOAD BEARING

Heavy products are no problem for densified hardwood pallets.

WATERPROOF RESIN

Keep on manufacturing with the same parameters. Consistent quality all the time.

HIGH DENSITY

Vibration Transmission is maximised due to the densified structure of the hardwood.

NO JOINTS

Single Flat Surface. Ensures perfect concrete surfaces, and long service pallet life.

RHINO Hardwood Composite Pallets for Concrete Block Machines

From the inception of its flawless performance to its positive environmental influences, RHINO concrete block machine pallets are manufactured from materials with excellent attributes for their application. This engineered hardwood with hard-wearing lamination surpasses any other pallet within the market worldwide today. RHINO pallets can be used with a clear conscience as we employ FSC certified plantation hardwood.

RHINO Production Pallets for Concrete Block Machines

RHINO Production Pallets can be utilised in all types of Concrete Block and Paver machines. The most common examples are as following :

- Production pallets for MASA Concrete Block Machines

- Production pallets for HESS Concrete Block Machines

- Production pallets for HAREX Concrete Block Machine

- Production pallets for ZENITH Concrete Block Machine

- Production pallets for KVM Concrete Block Machine

- Production Pallets for FRIMA Concrete Block Machine

- Production Pallets for OMAG Concrete Block Machine

- Production Pallets for REKERS Concrete Block Machine

- Production Pallets for PRENSOLAND Concrete Block Machine

RHINO

Hardwood Composite Pallets for Concrete Blocks

RHINO concrete paver pallets are created in a distinctive way ensuring that hardwood fibres are arranged as reinforcing elements thereby giving great strength and durability. Such a modern manufacturing process ensures that it outlasts many other kinds of materials.

The problems associated with pallets made from other materials, such as PVC and plastic pallets, are eradicated. This has been repeatedly confirmed via our Research & Development and scientific manufacturing processes in the creation of RHINO hardwood composite concrete brick pallets.

Rhino Hardwood Composite Pallets for Concrete Block Machine

RHINO Hardwood Composite pallets are manufactured from high-grade densified engineered hardwood to give it superior strength and durability. Hard-wearing lamination on top and bottom surfaces ensures excellent resistance to abrasion by pallets during concrete block production. The concrete block and paver manufacturing pallets, or production pallets, are single solid boards with no joints or gaps. Treated individually with industrial-strength waterproof resin, hardwood fibres are pressed under very high pressure and temperature. This creates exceedingly strong pallets for concrete blocks and pavers.

RHINO Hardwood Composite CONCRETE BLOCK MACHINES PALLETS

RHINO hardwood concrete block machine pallets are designed and manufactured to last longer in an abrasive environment. They are created in a distinctive way ensuring that hardwood fibres are arranged as reinforcing elements thereby giving great strength and durability. Use of waterproof resin during manufacturing ensures that our pallets stay resistant to moisture absorption. Steel mesh reinforcement on both sides of the pallet gives additional reinforcement to the pallet. It also ensures homogeneous distribution of vibration across the whole pallet surface. Such a modern manufacturing process ensures that RHINO pallets outlast many other kinds of materials. They are designed with high level of engineering to eradicate problems associated with pallets made from other materials, like plastic, softwood and steel. Our inhouse Research & Development has repeatedly confirmed superiority of scientific manufacturing processes in the creation of RHINO concrete block machine pallets. The sturdy hardwood used for manufacturing RHINO hardwood pallets has overcome quality issues arising from rusting, heavyweight and unevenness of steel surfaces. With a highly densified structure, vibration transmission to the green concrete is maximised resulting in higher production and reduced cycle time to our clients.

The sturdy hardwood used for designing our RHINO Hardwood Composite pallets has overcome some issues from rusting, heavyweight and unevenness of steel surfaces to the pollution created by PVC pallets. With a highly densified structure, vibration transmission to the green concrete is maximised which has resulted in consequent higher production and reduced cycle time to our clients.