RHINO Wooden Pallets for Concrete Blocks

Manufacturing Complex

Plantation Hardwood Timber

Select hardwood is chosen from plantation timbers around the world to manufacture wooden pallets for concrete blocks. Plantation timber is scientifically grown in conducive geographical regions ensuring that the forests are not destroyed for want of wood.

Log Processing

Plantation trees are manually selected to ensure physical parameters of logs as raw material for wooden pallets for concrete blocks. Logs are then fed into veneering machines where hydraulically operated sharp blades produce extremely thin layers of timber.

Hardwood Veneer

Hardwood Veneer forms the core of our wooden pallets for concrete blocks, and are of highest quality. Out of the veneers produced in the factory, ones with highest parameters are selected for Composite pallets. They are cross laid to increase the core strength.

Humidity Optimization

Humidity of veneer plays a very important part in the final quality of wooden pallets for concrete blocks. humidifying chambers are used to achieve the desired level of humidity before proceeding further. Optimum moisture is maintained during the whole process.

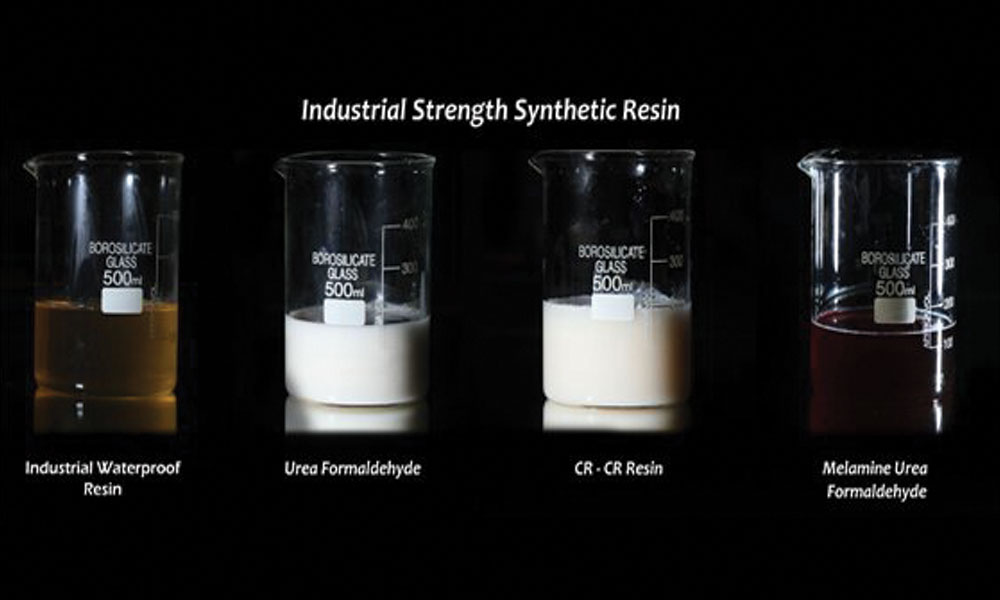

Waterproof Synthetic Resin

In-situ manufacturing of Industrial Strength Waterproof Synthetic Resin ensures consistent quality and availability of all grades of required resins for different applications. The Wooden Pallets For Concrete Blocks use the highest grade of Waterproof Synthetic Resin.

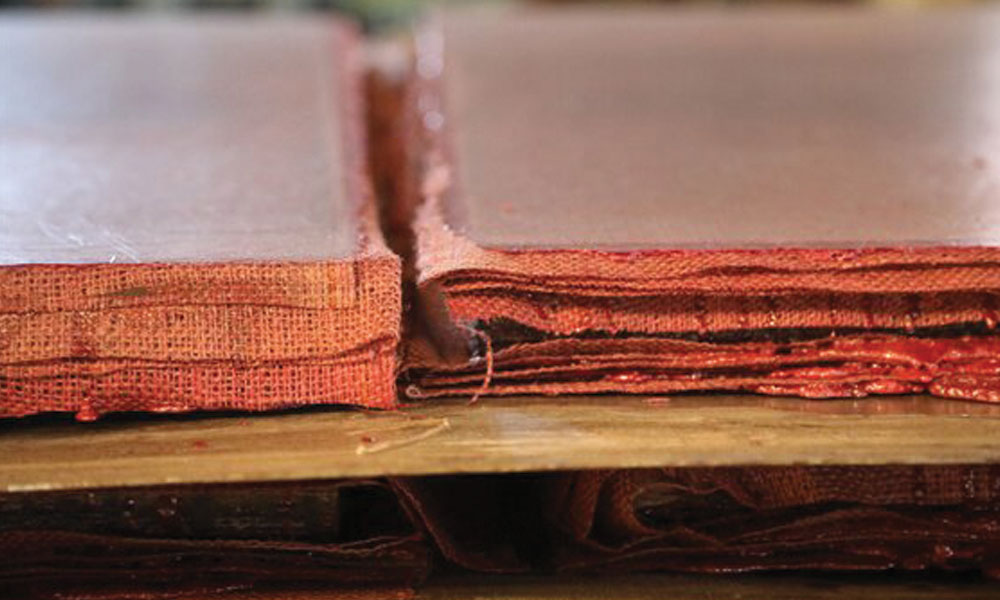

Resin Saturated Fibres

Individual veneer sheets are rolled through resin. Consistent quality control ensures 100% coverage by resin in each layer of hardwood fibres. This ensures absolute adhesion using superheated steam eventually producing high quality wooden pallets for concrete blocks.

Hydraulic Compression

Once the veneers are layered to optimum thickness, they are subject to 3,300 Tonnes of prolonged compression using superheated steam ensuring our wooden pallets for concrete blocks achieve the desired density and waterproof adhesiveness.

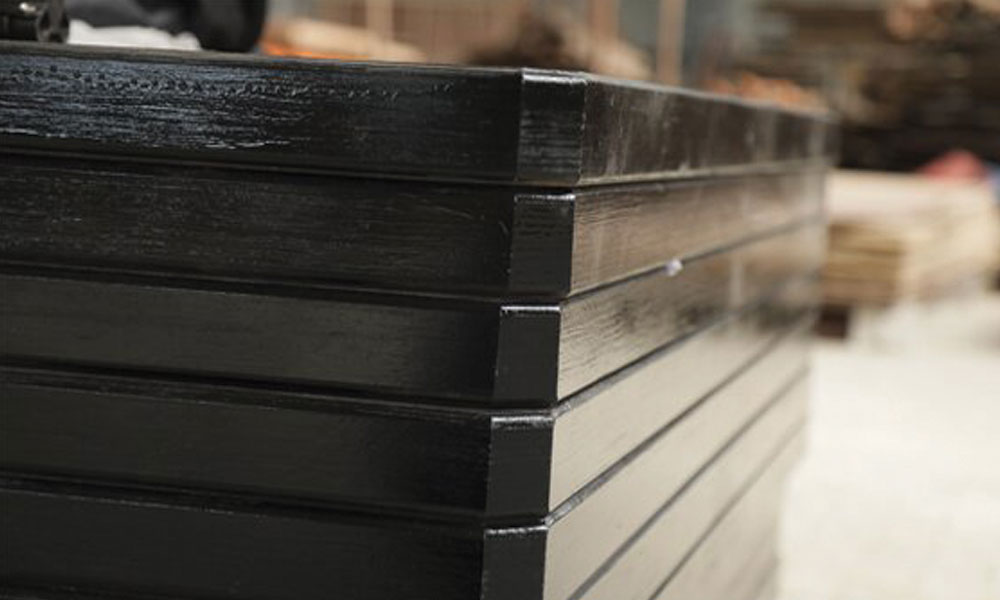

Pallet Core Formation

The Mother Board thus formed, is cut to size as per client requirements. Once cut to size, wooden pallets for concrete blocks go through calibration process on highly sensitive machines to achieve the required thickness and flatness as per client requirements.

Choice of Board Surfaces

Depending upon client requirements, the core is laminated under high temperature and pressure once again with multiple layers of Synthetic Film or Interwoven Fabric using waterproof resin. These layers ensure varying degrees of abrasion resistance increasing product life.

Edge and Corner Preparation

Post lamination, the corners of wooden pallets for concrete blocks are cut, and edges get chamfered to give a final finish. The edges are impregnated with Polyurethane based coatings to secure the edges. Our boards ensure high degree of dimensional tolerance.